在工业自动化中使用欧姆龙继电器的好处

工业自动化是利用控制系统(如计算机或机器人)和信息技术来处理工业中的不同过程和机械以取代人类。这是在工业化范围内超越机械化的第二步。

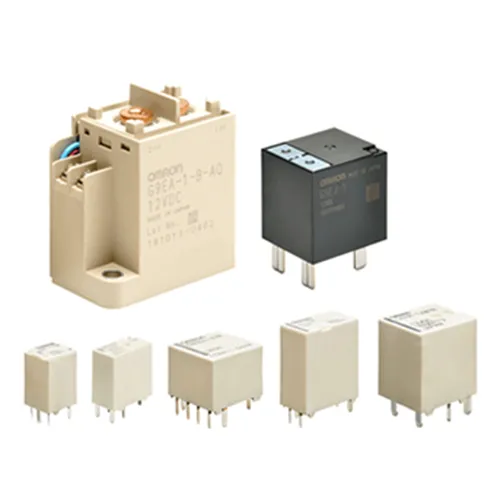

继电器是工业自动化的关键部件之一,它是一种通过由操作信号驱动的输出部分来切换电路的装置,该操作信号由开关设备控制的电输入信号触发。继电器用于各种用途,例如切换高压或大电流电路、隔离电路、保护电路和控制逻辑功能。

欧姆龙是继电器的领先制造商,为不同的应用和行业提供广泛的产品。欧姆龙继电器以其高质量、可靠性、高性能和创新性而闻名。在工业自动化中使用欧姆龙继电器的一些好处是:

欧姆龙继电器使用寿命长,故障率低,可降低维护成本和停机时间。

欧姆龙继电器具有很高的开关容量,可以处理大电流和电压,这使它们能够控制强大的设备和装置。

欧姆龙继电器响应时间快,灵敏度高,提高了控制系统的效率和精度。

欧姆龙继电器设计紧凑,功耗低,可节省控制面板的空间和能源。

欧姆龙继电器具有闭锁、棘轮、安全、固态、端子、I/O继电器类型等多种特性和功能,可以满足工业自动化系统的不同需求和要求。

总之,欧姆龙继电器是工业自动化应用的绝佳选择,因为它们比其他类型的继电器具有许多优势。欧姆龙继电器有助于提高工业过程的生产率、安全性、质量和盈利能力。